Displacement Intrusion Molding

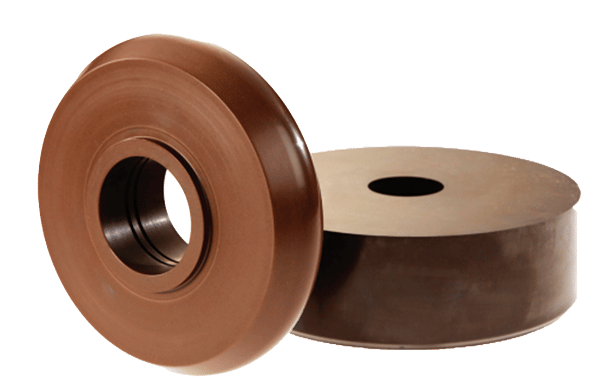

MMT&P has partnered with Specialty Polymers LLC to manufacture thick-wall stock shape cylinders, rods, tubes, and sheets from high-performance Engineering thermoplastics using a patent-pending Displacement Intrusion Molding (DIM) Process.

What is Displacement Intrusion Molding?

Displacement Intrusion Molding (DIM) is a culmination of nearly 20 years of research in high temperature/high-performance

engineering thermoplastic molding technology. The process has been developed to address the global need for superior quality,

thick-wall parts with large cross-sectional area which have not been successfully molded by the big 3 conventional molding processes (i.e., injection, compression, or extrusion molding).

The hybrid DIM process synergistically combines benefits from the big 3 conventional molding methods: extrusion, injection, and compression molding to provide exceptional results.

The DIM process is vastly more efficient in terms of time, energy, and labor. Savings due to this process are passed down to our customers.

Specialty Polymers, LLC has successfully molded some of the most top tier/high-performance thermoplastics in the market today, which include:

- PBI (Polybenzimidazole, Celazole® T-Series/TK-Series)

- PEEK(Poly-ether-ether-ketone) Victrex™, Solvay™

- PEKK (Poly-ether-ketone ketone, Kepstan™)

- PI (Polyimide, DuPont Vespel®)

- PPS (Polyphenylene sulfide, Ryton®)

- PEKK (Poly-ether-ketone ketone, Kepstan™)

Get A Free Quote

If you have a special manufacturing need, please reach out to our Experienced Team for a quote. We have what it takes to get your product made and to market.